| Energy saving and ECO system | |

| ▪ | Maximization of energy saving through independent control of each driving unit. |

| ▪ | Over 70% saving of energy comparing with hydraulic machine. |

| ▪ | Over 80% saving of cooling water by not using oil. |

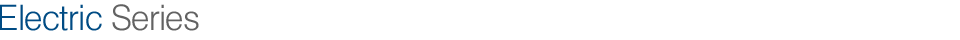

| Center press design through FEA (Finite Element Analysis) | |

| ▪ | Minimization of mold deformation |

| ▪ | Uniform clamping force |

| ▪ | Equalization of molding parts |

| ▪ | Improvement of molding stability for multi cavity |

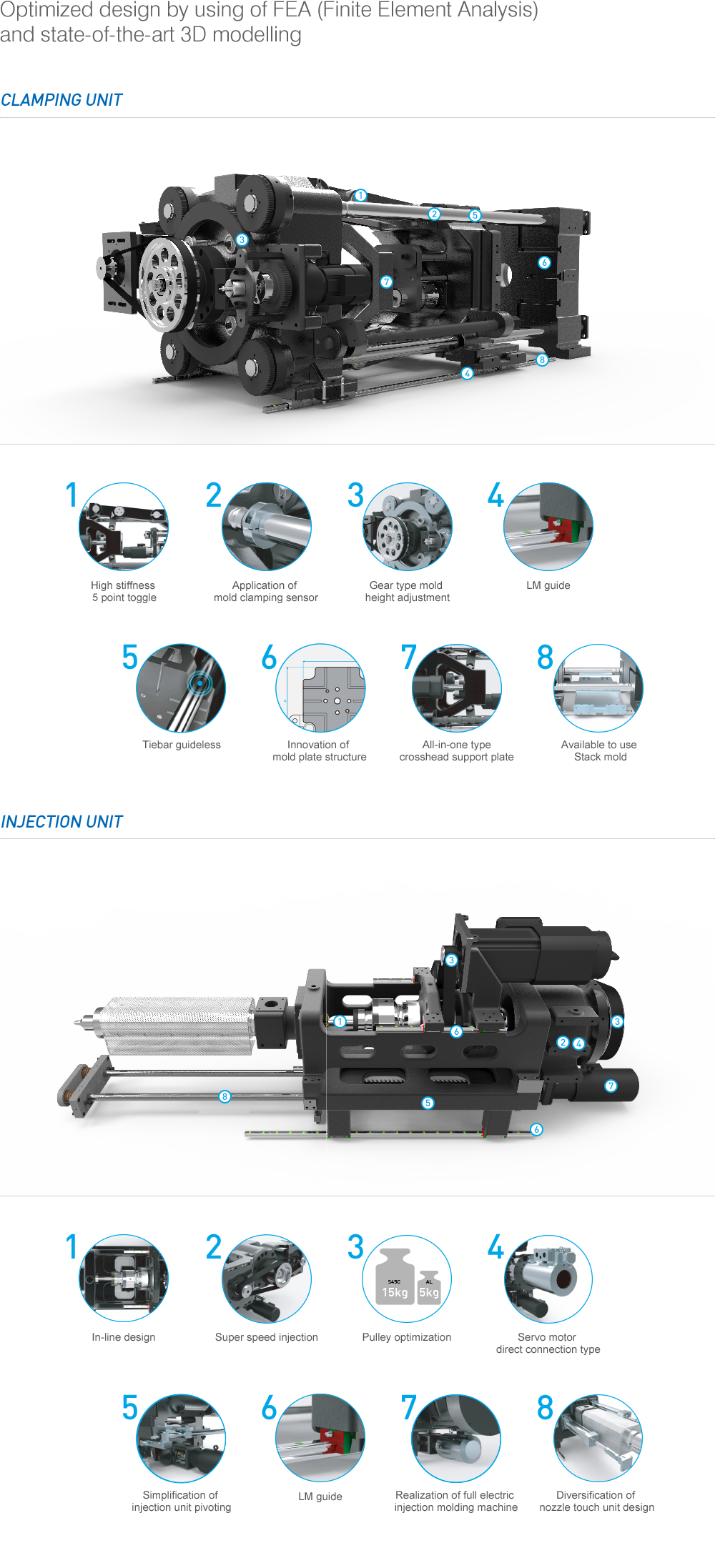

| Feature of GB SERIES | |

| ▪ | Improvement of operator's safety by hexagon cover design. |

| ▪ | The angle of controller unit can be adjusted by the electric cylinder to meet operator's eye level. |

| ▪ | Portable remote control key box. |

| Injection Unit | Model | 80 ton | ||||

| Item | Unit | S | A | B | ||

| Screw Diameter | mm | 25 | 28 | 32 | ||

| Standard | Injection Pressure | kg/cm² | 2800 | 2232 | 1709 | |

| Mpa | 275 | 219 | 168 | |||

| Holding Pressure | kg/cm² | 2240 | 1786 | 1367 | ||

| Mpa | 220 | 175 | 134 | |||

| Injection Speed | mm/sec | 400 | 400 | 400 | ||

| Injection Rate | cm³/sec | 196 | 246 | 322 | ||

| High Speed | Injection Pressure | kg/cm² | 2800 | 2232 | 1709 | |

| Mpa | 275 | 219 | 168 | |||

| Holding Pressure | kg/cm² | 2240 | 1786 | 1367 | ||

| Mpa | 220 | 175 | 134 | |||

| Injection Speed | mm/sec | 800 | 800 | 800 | ||

| Injection Rate | cm³/sec | 393 | 493 | 643 | ||

| Injection Stroke | mm | 120 | 120 | 120 | ||

| Shot Size | cm³ | 59 | 74 | 97 | ||

| Shot Weight | g | 54 | 68 | 89 | ||

| Plasticizing Capacity | kg/hr | 42 | 57 | 81 | ||

| Screw speed | rpm | 0~500 | ||||

| Clamping Unit (Double toggle) |

Clamping Force | ton | 80 |

| Space Between Tiebar(H x V) | mm | 420 x 420 | |

| Platen Size(H x V) | mm | 580 x 580 | |

| Opening Stroke | mm | 300 | |

| Max. Mold Weight | kg | 455 | |

| Min. Mold Height | mm | 150 | |

| Max. Mold Height | mm | 410 | |

| Ejector Force | ton | 2.5 | |

| Ejector Stroke | mm | 80 |

| General | Heater Capacity | kW | 10.3 |

| Machine Weight | ton | 4.8 | |

| Machine Size(L x W x H) | m | 4.53 x 1.51 x 1.65 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to customer side |

| Injection Unit | Model | 120 ton | ||||

| Item | Unit | S | A | B | ||

| Screw Diameter | mm | 28 | 32 | 36 | ||

| Standard | Injection Pressure | kg/cm² | 2400 | 1838 | 1452 | |

| Mpa | 235 | 180 | 142 | |||

| Holding Pressure | kg/cm² | 1920 | 1470 | 1162 | ||

| Mpa | 188 | 144 | 114 | |||

| Injection Speed | mm/sec | 400 | 400 | 400 | ||

| Injection Rate | cm³/sec | 246 | 322 | 407 | ||

| High Speed | Injection Pressure | kg/cm² | 2400 | 1838 | 1452 | |

| Mpa | 235 | 180 | 142 | |||

| Holding Pressure | kg/cm² | 1920 | 1470 | 1162 | ||

| Mpa | 188 | 144 | 114 | |||

| Injection Speed | mm/sec | 800 | 800 | 800 | ||

| Injection Rate | cm³/sec | 493 | 643 | 814 | ||

| Injection Stroke | mm | 160 | 160 | 160 | ||

| Shot Size | cm³ | 99 | 129 | 163 | ||

| Shot Weight | g | 91 | 119 | 150 | ||

| Plasticizing Capacity | kg/hr | 52 | 74 | 101 | ||

| Screw speed | rpm | 0~500 | ||||

| Clamping Unit (Double toggle) |

Clamping Force | ton | 120 |

| Space Between Tiebar(H x V) | mm | 460 x 460 | |

| Platen Size(H x V) | mm | 650 x 650 | |

| Opening Stroke | mm | 350 | |

| Max. Mold Weight | kg | 628 | |

| Min. Mold Height | mm | 150 | |

| Max. Mold Height | mm | 450 | |

| Ejector Force | ton | 3.5 | |

| Ejector Stroke | mm | 100 |

| General | Heater Capacity | kW | 11.5 |

| Machine Weight | ton | 6.5 | |

| Machine Size(L x W x H) | m | 5.25 x 1.96 x 1.78 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to customer side |

| Injection Unit | Model | 170 ton | ||||

| Item | Unit | S | A | B | ||

| Screw Diameter | mm | 36 | 40 | 45 | ||

| Standard | Injection Pressure | kg/cm² | 2300 | 1863 | 1472 | |

| Mpa | 225 | 183 | 144 | |||

| Holding Pressure | kg/cm² | 1840 | 1490 | 1178 | ||

| Mpa | 180 | 146 | 115 | |||

| Injection Speed | mm/sec | 250 | 250 | 250 | ||

| Injection Rate | cm³/sec | 254 | 314 | 398 | ||

| High Speed | Injection Pressure | kg/cm² | 2300 | 1863 | 1472 | |

| Mpa | 225 | 183 | 144 | |||

| Holding Pressure | kg/cm² | 1840 | 1490 | 1178 | ||

| Mpa | 180 | 146 | 115 | |||

| Injection Speed | mm/sec | 500 | 500 | 500 | ||

| Injection Rate | cm³/sec | 509 | 628 | 795 | ||

| Injection Stroke | mm | 180 | 180 | 180 | ||

| Shot Size | cm³ | 183 | 226 | 286 | ||

| Shot Weight | g | 167 | 206 | 261 | ||

| Plasticizing Capacity | kg/hr | 78 | 103 | 141 | ||

| Screw speed | rpm | 0~350 | ||||

| Clamping Unit (Double toggle) |

Clamping Force | ton | 170 |

| Space Between Tiebar(H x V) | mm | 520 x 520 | |

| Platen Size(H x V) | mm | 740 x 740 | |

| Opening Stroke | mm | 400 | |

| Max. Mold Weight | kg | 904 | |

| Min. Mold Height | mm | 220 | |

| Max. Mold Height | mm | 500 | |

| Ejector Force | ton | 4.0 | |

| Ejector Stroke | mm | 120 |

| General | Heater Capacity | kW | 12.65 |

| Machine Weight | ton | 8.6 | |

| Machine Size(L x W x H) | m | 5.96 x 1.98 x 1.86 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to customer side |

| Injection Unit | Model | 250 ton | ||||

| Item | Unit | S | A | B | ||

| Screw Diameter | mm | 45 | 50 | 55 | ||

| Standard | Injection Pressure | kg/cm² | 2200 | 1782 | 1473 | |

| Mpa | 216 | 175 | 144 | |||

| Holding Pressure | kg/cm² | 1760 | 1426 | 1178 | ||

| Mpa | 173 | 140 | 115 | |||

| Injection Speed | mm/sec | 200 | 200 | 200 | ||

| Injection Rate | cm³/sec | 318 | 393 | 475 | ||

| High Speed | Injection Pressure | kg/cm² | 2200 | 1782 | 1473 | |

| Mpa | 216 | 175 | 144 | |||

| Holding Pressure | kg/cm² | 1760 | 1426 | 1178 | ||

| Mpa | 173 | 140 | 115 | |||

| Injection Speed | mm/sec | 400 | 400 | 400 | ||

| Injection Rate | cm³/sec | 636 | 785 | 950 | ||

| Injection Stroke | mm | 200 | 200 | 200 | ||

| Shot Size | cm³ | 318 | 393 | 475 | ||

| Shot Weight | g | 286 | 353 | 428 | ||

| Plasticizing Capacity | kg/hr | 128 | 158 | 192 | ||

| Screw speed | rpm | 0~350 | ||||

| Clamping Unit (Double toggle) |

Clamping Force | ton | 220 |

| Space Between Tiebar(H x V) | mm | 610 x 610 | |

| Platen Size(H x V) | mm | 890 x 890 | |

| Opening Stroke | mm | 550 | |

| Max. Mold Weight | kg | 1550 | |

| Min. Mold Height | mm | 250 | |

| Max. Mold Height | mm | 650 | |

| Ejector Force | ton | 5.0 | |

| Ejector Stroke | mm | 130 |

| General | Heater Capacity | kW | 19.88 |

| Machine Weight | ton | 14 | |

| Machine Size(L x W x H) | m | 7.09 x 2.02 x 2.15 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to customer side |

| Injection Unit | Model | 330 ton | ||||

| Item | Unit | S | A | B | ||

| Screw Diameter | mm | 50 | 55 | 60 | ||

| Standard | Injection Pressure | kg/cm² | 2400 | 1983 | 1667 | |

| Mpa | 235 | 194 | 163 | |||

| Holding Pressure | kg/cm² | 1920 | 1586 | 1334 | ||

| Mpa | 188 | 156 | 131 | |||

| Injection Speed | mm/sec | 200 | 200 | 200 | ||

| Injection Rate | cm³/sec | 393 | 475 | 565 | ||

| High Speed | Injection Pressure | kg/cm² | 2400 | 1983 | 1667 | |

| Mpa | 235 | 194 | 163 | |||

| Holding Pressure | kg/cm² | 1920 | 1586 | 1334 | ||

| Mpa | 188 | 156 | 131 | |||

| Injection Speed | mm/sec | 400 | 400 | 400 | ||

| Injection Rate | cm³/sec | 785 | 950 | 1131 | ||

| Injection Stroke | mm | 240 | 240 | 240 | ||

| Shot Size | cm³ | 471 | 570 | 679 | ||

| Shot Weight | g | 429 | 519 | 618 | ||

| Plasticizing Capacity | kg/hr | 121 | 156 | 197 | ||

| Screw speed | rpm | 0~250 | ||||

| Clamping Unit (Double toggle) |

Clamping Force | ton | 300 |

| Space Between Tiebar(H x V) | mm | 720 x 720 | |

| Platen Size(H x V) | mm | 1030 x 1030 | |

| Opening Stroke | mm | 630 | |

| Max. Mold Weight | kg | 2627 | |

| Min. Mold Height | mm | 300 | |

| Max. Mold Height | mm | 750 | |

| Ejector Force | ton | 6.0 | |

| Ejector Stroke | mm | 150 |

| General | Heater Capacity | kW | 26.03 |

| Machine Weight | ton | 18 | |

| Machine Size(L x W x H) | m | 7.91 x 2.18 x 2.25 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to customer side |

TEL. +82-51-320-8700, 8800 FAX. +82-51-320-8793

3, Sinhang 7-ro, Jinhae-gu, Changwon-si, Gyeongsangnam-do, Republic of Korea

Copyright © DONGSHIN All rights reserved.