| ▪ | Optimizing to produce multi cavity products |

| ▪ | High sensitive mold protection |

| ▪ | Cycle time reduction by high speed pressure increasing |

| ▪ | Securement of the operator's safety by dividing molding and taking out position. |

| ▪ | Maximizing the operator's convenience by combining vertical clamping unit with horizontal injection unit. |

| ▪ | Improvement of position repeatability by table lock pin system. |

| Injection Unit | ||||||||||||

| Model | CS25 | CS45 | VR60H | VR85H | VR150H | VR200H | ||||||

| Item | Unit | |||||||||||

| Injection Unit | type | Horizontal | ||||||||||

| Screw Type | type | A | A | B | A | B | A | B | A | B | A | B |

| Screw Diameter | mm | 22 | 36 | 40 | 36 | 40 | 36 | 40 | 45 | 50 | 55 | 60 |

| Shot Weight (PS) | g | 17 | 111 | 137 | 111 | 137 | 111 | 137 | 317 | 392 | 540 | 642 |

| Shot Size | cm³ | 19 | 122 | 150 | 122 | 150 | 122 | 150 | 349 | 431 | 593 | 706 |

| Injection Pressure | kg/cm³ | 1247 | 1840 | 1491 | 1840 | 1491 | 1840 | 1491 | 1919 | 1554 | 1833 | 1540 |

| Injection Rate | cm³/sec | 57 | 91 | 112 | 91 | 112 | 91 | 112 | 134 | 165 | 226 | 269 |

| Plasticizing Capacity | kg/hr | 13.6 | 50 | 67 | 50 | 67 | 50 | 67 | 79 | 100 | 145 | 183 |

| Screw Speed | rpm | 0~300 | 0~231 | 0~231 | 0~231 | 0~198 | 0~213 | |||||

| Clamping Unit | |||||||

| Model | CS25 | CS45 | VR60H | VR85H | VR150H | VR200H | |

| Item | Unit | Slide(Bed) | Slide(Bed) | Table | Table | Table | Table |

| Clamping Unit | type | Vertical | |||||

| Clamping System | type | Frame | Frame | Tie bar | Tie bar | Tie bar | Tie bar |

| Clamping Force | ton | 25 | 45 | 60 | 85 | 150 | 200 |

| Opening Stroke | mm | 150 | 185 | 280 | 250 | 370 | 370 |

| Min. Mold Height | mm | 190 | 235 | 235 | 250 | 250 | 380 |

| Bottom Mold Height | mm | 110 | 150 | 150 | 150 | 150 | 250 |

| Daylight | mm | 340 | 420 | 515 | 500 | 620 | 750 |

| Slide Platen Stroke | mm | 450 | 450 | - | - | - | - |

| Slide Platen Size (H x V) | mm | 900x260 | 900x340 | - | - | - | - |

| Bed Platen Size (H x V) | mm | 630x260 | 630x340 | - | - | - | - |

| Ejector Stroke | mm | 60 | 60 | 60 | 60 | 70 | 70 |

| Table Diameter | mm | - | - | 1000 | 1100 | 1170 | 1370 |

| General | |||||||

| Model | CS25 | CS45 | VR60H | VR85H | VR150H | VR200H | |

| Item | Unit | ||||||

| Heater Capacity | kW | 2.2 | 5.8 | 5.8 | 6.9 | 7.5 | 11.95 |

| Pump Motor Capacity | kW | 7.5 | 11 | 11 | 18.5 | 22 | 30 |

| Total Electric Capacity | kW | 10.9 | 18 | 18 | 26.6 | 30.7 | 43.15 |

| Oil Tank Capacity | ℓ | 200 | 300 | 300 | 350 | 350 | 600 |

| Machine Size (L x W x H) | m | 1.9x1.7x2.0 | 2.6x1.7x2.1 | 3.1x1.4x2.0 | 3.3x1.6x2.0 | 3.7x2.0x3.1 | 4.1x2.1x3.2 |

| Machine Weight | ton | 2.8 | 4.1 | 4.2 | 5.0 | 10.5 | 14 |

| Water Requirement | ℓ/min | 20 | 30 | 30 | 38 | 44 | 60 |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Total wattage = Heater power + pump motor power + system power. |

| • | Water requirement is not considered mold cooling but considered only injection molding machine. |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to the customer side |

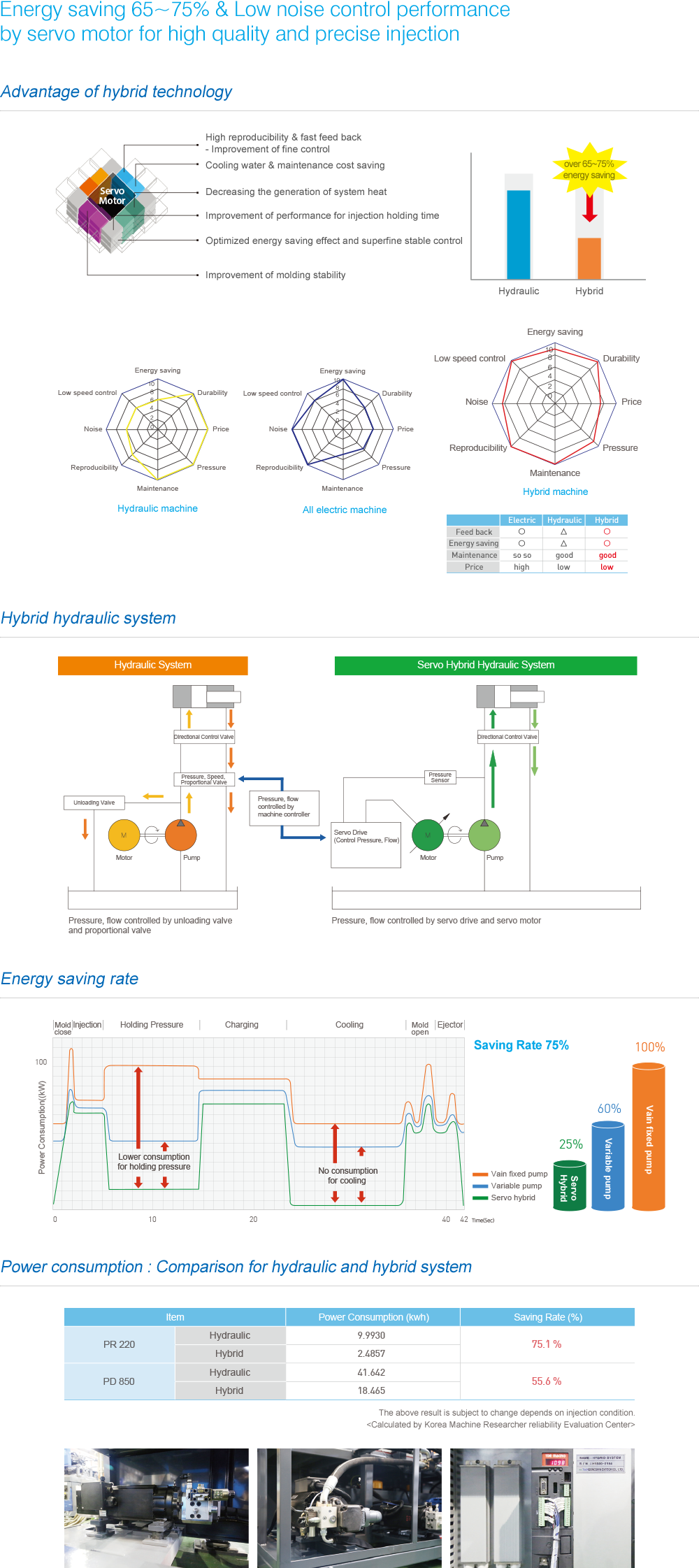

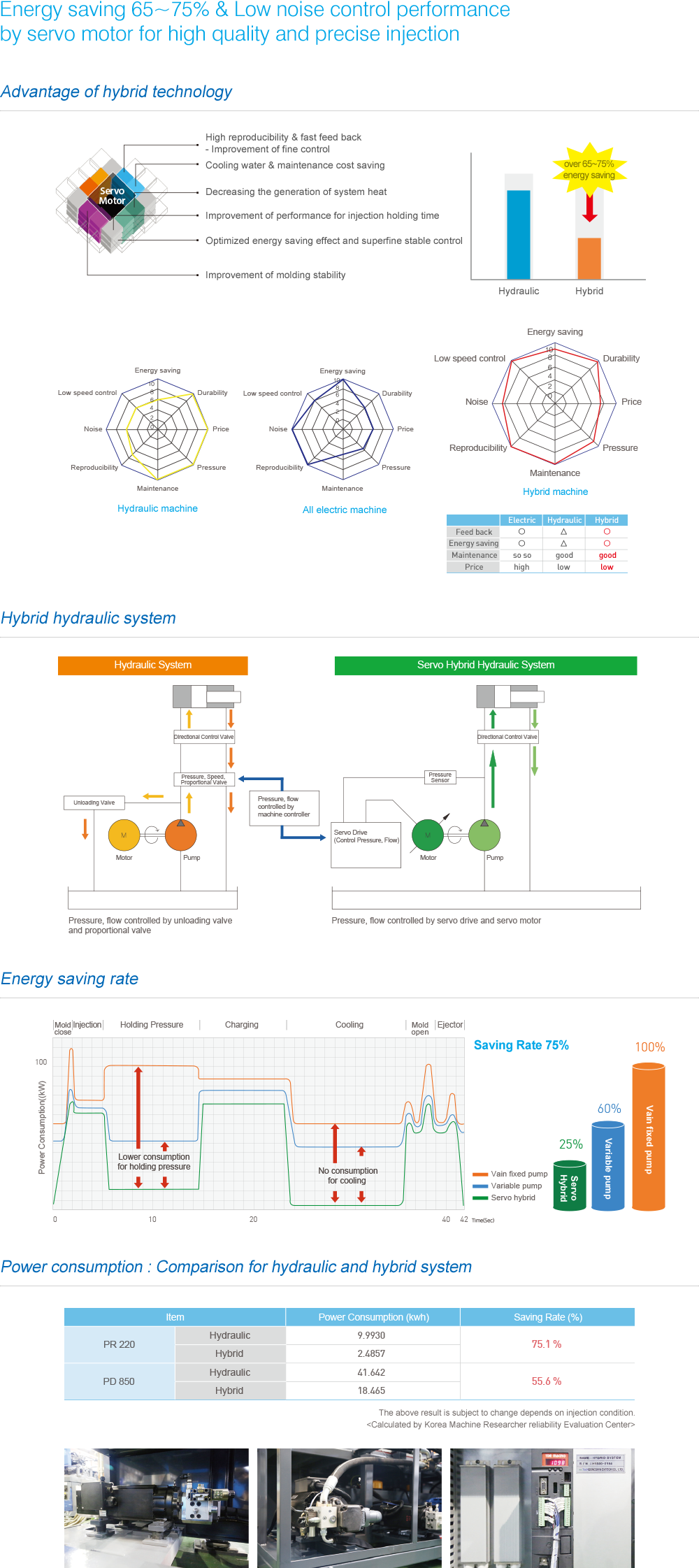

| • | Option : Hybrid system |

| ▪ | Optimizing to produce multi cavity products |

| ▪ | High sensitive mold protection |

| ▪ | Cycle time reduction by high speed pressure increasing |

| ▪ | Securement of the operator's safety by dividing molding and taking out position. |

| ▪ | Maximizing the operator's convenience by combining vertical clamping unit with horizontal injection unit. |

| ▪ | Improvement of productivity and safety by moving slide platen (VS series) |

| Injection Unit | ||||||||||||

| Model | VS/VB30 | VS/VB60 | VS/VB85 | VS/VB150 | VS/VB220 | |||||||

| Item | Unit | |||||||||||

| Injection Unit | type | Vertical | ||||||||||

| Screw Type | type | A | B | A | B | A | B | A | B | A | B | |

| Screw Diameter | mm | 25 | 28 | 28 | 32 | 36 | 40 | 45 | 50 | 55 | 60 | |

| Shot Weight (PS) | g | 45 | 56 | 67 | 88 | 137 | 169 | 318 | 392 | 480 | 571 | |

| Shot Size | cm³ | 49 | 61.5 | 73.8 | 96.5 | 150 | 186 | 349 | 431 | 527 | 627 | |

| Injection Pressure | kg/cm³ | 2329 | 1857 | 1857 | 1422 | 1840 | 1491 | 1919 | 1554 | 1833 | 1540 | |

| Injection Rate | cm³/sec | 39 | 49 | 91 | 112 | 91 | 112 | 134 | 165 | 226 | 269 | |

| Plasticizing Capacity | kg/hr | 16 | 19 | 50 | 67 | 50 | 67 | 79 | 100 | 145 | 183 | |

| Screw Speed | rpm | 0~240 | 0~231 | 0~231 | 0~198 | 0~213 | ||||||

| Clamping Unit | |||||||

| Model | VS/VB30 | VS/VB60 | VS/VB85 | VS/VB150 | VS/VB220 | ||

| Item | Unit | Slide/Bed | Slide/Bed | Slide/Bed | Slide/Bed | Slide/Bed | |

| Clamping Unit | type | Vertical | |||||

| Clamping System | type | Tie Bar | |||||

| Clamping Force | ton | 30 | 60 | 85 | 150 | 220 | |

| Opening Stroke | mm | 260 | 280 | 250 | 330 | 300 | |

| Min. Mold Height | mm | 160 | 180 | 250 | 300 | 350 | |

| Max. Mold Height | mm | 420 | 460 | 500 | 630 | 650 | |

| Space Between Tiebar (H x V) |

mm | 270x295 270x270 |

350x350 350x350 |

330x470 470x330 |

400x460 | 460x610 610x450 |

|

| Platen Size (H x V) | mm | 410x435 410x410 |

520x520 515x515 |

500x640 640x500 |

625x685 685x625 |

730x890 890x730 |

|

| Slide Platen Size (H x V) | mm | 900x265 | 1050x340 | 1100x460 | 1200x460 | 1400x600 | |

| Slide Platen Stroke | mm | 450 - | 500 - | 550 - | 600 - | 700 - | |

| Ejector Stroke | mm | 60 | 60 | 65 | 80 | 110 | |

| General | |||||||

| Model | VS/VB30 | VS/VB60 | VS/VB85 | VS/VB150 | VS/VB220 | ||

| Item | Unit | ||||||

| Heater Capacity | kW | 2.7 | 3.5 | 6.3 | 7.8 | 9.7 | |

| Pump Motor Capacity | kW | 7.5 | 11 | 18.5 | 22 | 30 | |

| Total Electric Capacity | kW | 11.4 | 15.7 | 26 | 31 | 40.9 | |

| Oil Tank Capacity | ℓ | 250 | 300 | 350 | 350 | 500 | |

| Machine Size (L x W x H) | m | 1.3x1.8x2.9[2.4] 1.3x1.3x2.9[2.3] |

1.6x2.0x3.2[2.6] 1.4x1.4x3.1[2.4] |

1.7x2.0x3.6[2.9] 1.5x1.5x3.5[2.8] |

1.8x2.2x4.5 1.8x1.9x4.6 |

2.2x2.6x5.0[4.1] 2.2x2.2x5.0[4.0] |

|

| Machine Weight | ton | 3.2 | 3.6 | 4.3 | 7.5 | 10.5 10.0 | |

| Water Requirement | ℓ/min | 20 | 30 | 38 | 44 | 60 | |

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Total wattage = Heater power + pump motor power + system power. |

| • | Water requirement is not considered mold cooling but considered only injection molding machine. |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to the customer side |

| • | Option : Hybrid system |

| ▪ | Optimizing to produce multi cavity products |

| ▪ | High sensitive mold protection |

| ▪ | Cycle time reduction by high speed pressure increasing |

| ▪ | Securement of the operator's safety by dividing molding and taking out position. |

| ▪ | Accurate control of high speed rotation by Servo Motor |

| ▪ | Improvement of position repeatability by table lock pin system. |

| Injection Unit | ||||||||||||

| Model | VR30 | VR60 | VR85 | VR110 | ||||||||

| Item | Unit | |||||||||||

| Injection Unit | type | Vertical | ||||||||||

| Screw Type | type | A | B | A | B | A | B | A | B | |||

| Screw Diameter | mm | 25 | 28 | 28 | 32 | 36 | 40 | 36 | 40 | |||

| Shot Weight (PS) | g | 45 | 56 | 67 | 88 | 111 | 137 | 111 | 137 | |||

| Shot Size | cm³ | 49 | 61.5 | 73.8 | 96.5 | 122 | 150 | 122 | 150 | |||

| Injection Pressure | kg/cm³ | 2329 | 1857 | 1857 | 1422 | 1483 | 1201 | 1483 | 1201 | |||

| Injection Rate | cm³/sec | 39 | 49 | 67 | 87 | 123 | 152 | 123 | 152 | |||

| Plasticizing Capacity | kg/hr | 16 | 19 | 24 | 29 | 56 | 75 | 56 | 75 | |||

| Screw Speed | rpm | 0~240 | 0~250 | 0~250 | 0~250 | |||||||

| Clamping Unit | |||||||

| Model | VR30 | VR60 | VR85 | VR110 | |||

| Item | Unit | Table | Table | Table | Table | ||

| Clamping Unit | type | Vertical | |||||

| Clamping System | type | Tie Bar | |||||

| Clamping Force | ton | 30 | 60 | 85 | 110 | ||

| Opening Stroke | mm | 260 | 280 | 250 | 300 | ||

| Min. Mold Height | mm | 160 | 180 | 250 | 300 | ||

| Max. Mold Height | mm | 420 | 460 | 500 | 600 | ||

| Table Diameter | mm | 860 | 1000 | 1150 | 1300 | ||

| Ejector Stroke | mm | 60 | 60 | 70 | 80 | ||

| General | |||||||

| Model | VR30 | VR60 | VR85 | VR110 | |||

| Item | Unit | ||||||

| Heater Capacity | kW | 2.7 | 3.5 | 7.5 | 7.5 | ||

| Pump Motor Capacity | kW | 7.5 | 11 | 18.5 | 18.5 | ||

| Total Electric Capacity | kW | 11.4 | 15.7 | 33 | 33.8 | ||

| Oil Tank Capacity | ℓ | 250 | 300 | 350 | 350 | ||

| Machine Size (L x W x H) | m | 2.0x1.4x2.9[2.3] | 2.0x1.5x3.2[2.6] | 2.2x1.6x3.6[2.9] | 2.2x1.9x4.0[3.2] | ||

| Machine Weight | ton | 3.2 | 3.5 | 4.7 | 7.0 | ||

| Water Requirement | ℓ/min | 20 | 30 | 38 | 38 | ||

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Total wattage = Heater power + pump motor power + system power. |

| • | Water requirement is not considered mold cooling but considered only injection molding machine. |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to the customer side |

| • | Option : Hybrid system |

| ▪ | Optimizing to produce multi cavity products |

| ▪ | High sensitive mold protection |

| ▪ | Cycle time reduction by high speed pressure increasing |

| ▪ | Securement of the operator's safety by dividing molding and taking out position. |

| ▪ | Vertical type type clamp and horizontal type injection unit |

| ▪ | Improvement of productivity and production stability by left & right slide plate system (VS series) |

| Injection Unit | ||||||||||||

| Model | VS/VB85H | VS/VB150H | VB180H | VB350H | ||||||||

| Item | Unit | |||||||||||

| Injection Unit | type | Horizontal | ||||||||||

| Screw Type | type | A | B | A | B | A | B | A | B | |||

| Screw Diameter | mm | 36 | 40 | 45 | 50 | 45 | 50 | 55 | 60 | |||

| Shot Weight (PS) | g | 137 | 169 | 318 | 392 | 318 | 392 | 539 | 642 | |||

| Shot Size | cm³ | 150 | 186 | 349 | 431 | 349 | 431 | 593 | 706 | |||

| Injection Pressure | kg/cm³ | 1840 | 1491 | 1919 | 1554 | 1919 | 1554 | 1833 | 1540 | |||

| Injection Rate | cm³/sec | 91 | 112 | 134 | 165 | 134 | 165 | 227 | 270 | |||

| Plasticizing Capacity | kg/hr | 50 | 67 | 79 | 100 | 79 | 100 | 145 | 183 | |||

| Screw Speed | rpm | 0~231 | 0~198 | 0~198 | 0~250 | |||||||

| Clamping Unit | |||||||

| Model | VS/VB85H | VS/VB150H | VB180H | VB350H | |||

| Item | Unit | Slide/Bed | Slide/Bed | Bed | Bed | ||

| Clamping Unit | type | Vertical | |||||

| Clamping System | type | Tie Bar | |||||

| Clamping Force | ton | 85 | 150 | 180 | 350 | ||

| Opening Stroke | mm | 250 | 370 | 370 | 500 | ||

| Min. Mold Height | mm | 250 | 250 | 330 | 380 | ||

| Bottom Mold Height | mm | 150 | 150 | 170 | 250 | ||

| Daylight | mm | 500 | 620 | 700 | 880 | ||

| Space Between Tiebar (H x V) |

mm | 330x470 470x330 |

400x460 460x400 |

460x400 | 1400x450 | ||

| Platen Size (H x V) | mm | 500x640 640x500 |

625x685 685x325 |

695x635 | 1760x810 | ||

| Slide Platen Size (H x V) | mm | 1100x460 - |

1200x456 - |

- | - | ||

| Ejector Stroke | mm | 60 | 80 | 80 | 120 | ||

| General | |||||||

| Model | VS/VB85H | VS/VB150H | VB180H | VB350H | |||

| Item | Unit | ||||||

| Heater Capacity | kW | 6.9 | 7.5 | 7.5 | 10 | ||

| Pump Motor Capacity | kW | 18.5 | 22 | 22 | 37 | ||

| Total Electric Capacity | kW | 26.6 | 30.7 | 30.7 | 50.2 | ||

| Oil Tank Capacity | ℓ | 350 | 380 | 380 | 800 | ||

| Machine Size (L x W x H) | m | 3.1x2.0x2.1 | 3.1x2.2x2.8 | 3.1x2.2x2.8 | 3.7x2.2x3.8 | ||

| Machine Weight | ton | 4.8 | 6.8 | 7.0 | 16.0 | ||

| Water Requirement | ℓ/min | 38 | 44 | 48.4 | 74 | ||

| • | Shot Size = Cross sectional area of screw diameter x screw stroke |

| • | Shot weight = Shot size x material constant |

| • | Total wattage = Heater power + pump motor power + system power. |

| • | Water requirement is not considered mold cooling but considered only injection molding machine. |

| • | Above data can be changed according to the manufacturer's R&D plan without notice to the customer side |

| • | Option : Hybrid system |

| ▪ | INJECTION |

- |

Inject the melted material into the mold using low pressure |

| ▪ | Bolster & Moving Unit |

- |

Device to install bottom mold |

| - | Installed on the right side 1set & left side 1set from the center of injection M/C |

| - | Transferring the bolster left and right side by hydraulic motor |

| ▪ | Structure |

- |

Clamping unit - Crown, Moving plate, Bolster, Rotary Plate, Oil Tank. |

| ▪ | Features |

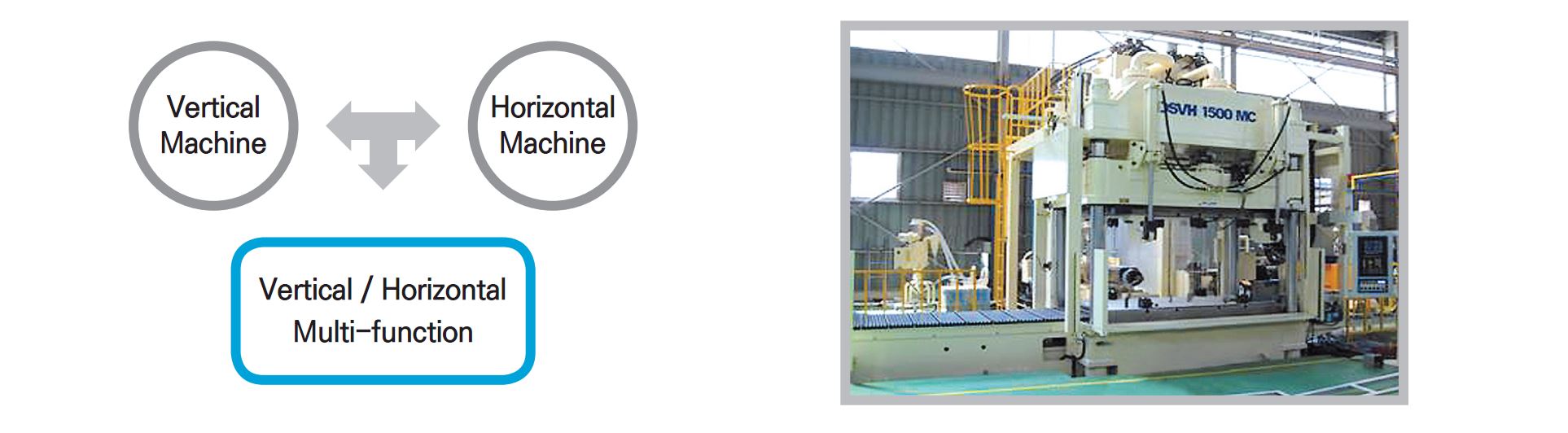

- |

Take advantage of strong point from vertical & horizontal machine |

| - | High speed movement and precise positioning of bottom platen by Servo motor. |

| - | Easy insert process by 90° rotation of top platen and realization of high speed cycle. |

| ▪ | 1 (one) cycle |

- |

Rising of top platen (mold open) → Bolster transferring left side |

| → Descent of top side rotary platen → Ascent of top side rotary platen | |

| → Bolster transferring right side → Falling of top platen (mold close) | |

| → Injection unit forward → Injection → Injection unit backward |

TEL. +82-51-320-8700, 8800 FAX. +82-51-320-8793

3, Sinhang 7-ro, Jinhae-gu, Changwon-si, Gyeongsangnam-do, Republic of Korea

Copyright © DONGSHIN All rights reserved.